Model: Fedar FD1900 Sublimation Printer

Max Printing Width: 1900mm

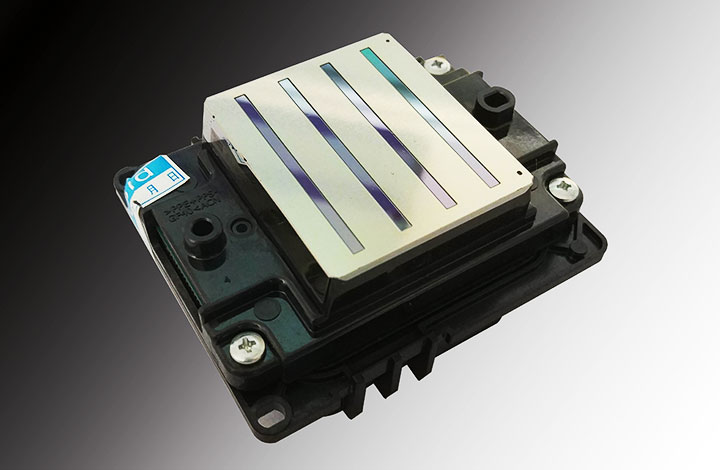

Printer Head: 2 Epson I3200-A1 Heads

Max Printing Resolution: 3200DPI

Max Printing Speed: 2pass 105 Sqm/hr

TECHNICAL DATA:

|

Model |

Fedar FD1900 Sublimation Printer |

| Printing Size | 1900mm |

| Printhead | 2 EPSON Original I3200-A1 Heads |

|

Printing Speed

|

360*1200dpi 2PASS: 105m/h 360*2400&720*1200dpi 4PASS: 55m2/h

360*1800dpi 3PASS: 70m/h 360*3600&720*1800dpi 6PASS: 35m2/h |

| Max Resolution | 3200DPI |

| Ink Color |

Double C M Y K |

|

Ink Type |

Water-Based Ink, Pigment Ink, Sublimation Ink |

|

RIP Software |

MAINTOP6.0, PHOTOPRINT, ONYX, NEOSTAMPA |

| Interface | Gigabit Port |

|

Print File Format |

BMP, TIF, JPG, PDF Etc. |

| Heating System |

Extra Front Heating System |

|

Feeding Method |

Roll to Roll, Leaf |

| Color Management | ICC Based; Density & Curves Adjustable |

| Power Supply |

50HZ/60HZ, 110~220V, 10A |

| Gross Weight | 600KGS |

| Working Environment Temperature | 20C-35C (68F-95F) |

| Working Environment Humidity | 35%-65%Rh |

| Package Size (L*W*H) | 3020mm*940mm*1110mm |

DETAILS:

Fedar FD1900 Dye Sublimation Printer uses double Epson 3200 printing heads. It uses TFP thin film piezoelectric technology and 2.5PL variable dot ink drop function, accurately positioning the ink drop, the image color layer is richer and fuller, and the printing effect is more exquisite. The Epson3200 head adopts automatic cleaning and automatic flash spray function to prevent blockage.

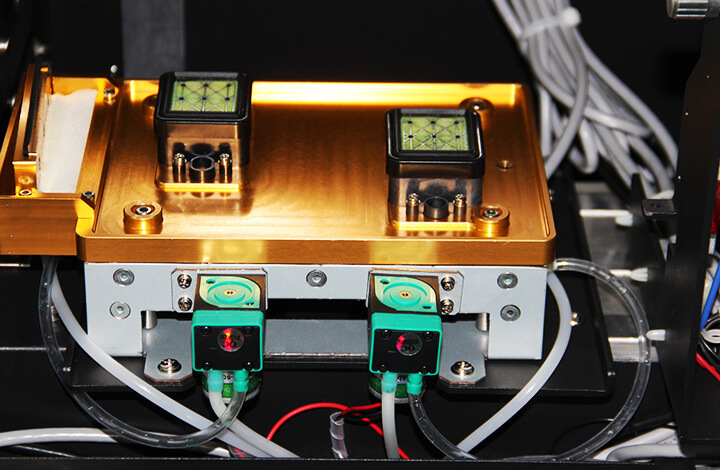

FD1900 sublimation printer equipped with advanced intelligent nozzle cleaning and moisturizing device, providing safe and convenient nozzle cleaning and maintenance functions, making operation and maintenance more convenient. The working principle of the automatic ink cleaning function: the digital printing machine draws the ink through the nozzle of the ink pump in the ink stack to achieve the purpose of cleaning and moisturizing, preventing the nozzle from clogging.

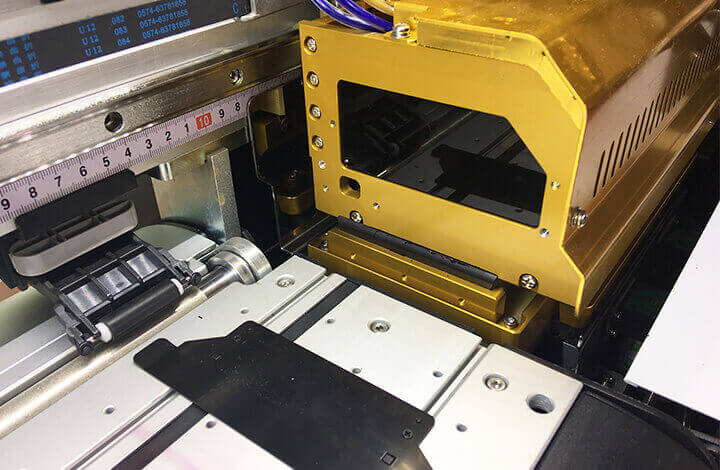

The height of the double-head nozzle independently developed can be adjusted arbitrarily, and it can flexibly respond to different thicknesses of printing materials. The anti-scratch-paper function on both sides of the small frame can reduce the damage of the nozzle caused by the paper tilting.

The assembly precision of the machine printing platform is controlled within plus or minus 7.5 wires, which lays the foundation for high-precision and high-quality production. The overall honeycomb aluminum alloy platform is hard-oxidized on the surface and will not deform for a long time.

FD1900 sublimation printer uses four 3L super-large-capacity ink tank with independent and continuous ink supply. The powerful continuous supply ink supply system provides support for the improvement of production efficiency, avoiding the frequent shortage of ink in production and the heavy work caused by back and forth inspection.

Intelligent ink shortage system reminding, reduces the tediousness of frequently checking the remaining ink, and promptly reminds to add ink to ensure the continuity of printing work.

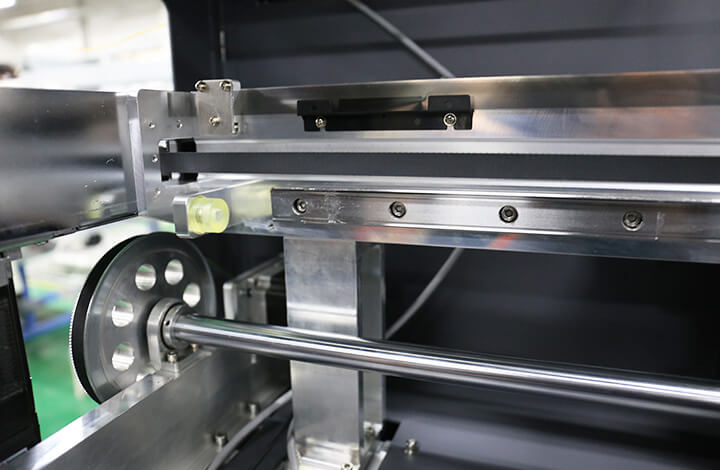

The core components are made of high-quality industry accessories such as Japanese THK ultra-quiet linear guide rails, Japanese NSK bearings, German IGUS INK chain, LEADSHINE servo motor, etc. All of these ensure the accuracy of the machine and the stability of long-term work.

This taking up system can ensure that the left and right sides of the paper-receiving paper have the same pulling force; the rewinding is tidy and does not deviate.

FD1900 sublimation printer synchronized with printing, energy saving and emission reduction, the temperature can be adjusted according to the actual situation during printing.

The whole frame is welded with square steel, industrial grade design, the whole structure is strong and stable, which ensures that the equipment is stable and does not shake during the high-speed printing process.

Model: Fedar FD1900 Sublimation Printer

Printing Width: 1900mm

Print Head: 2 Epson Original I3200-A1 Heads

Interface: Gigabit LAN

Print Media: Transfer Paper

Drying Method: Extra Dryer Device

RIP Software: Maintop, Onyx, Photo Print

Ink Supply Method : Bulk Ink Supply System

Printing File Forms: TIFF, JPG, EPS, PDF, etc.

Media Transfer: Auto Taking-Up Media Device

Ink Type: Sublimation Ink, Water Based Dye Ink

If you need our products please write down any questions, we will reply as soon as possible.