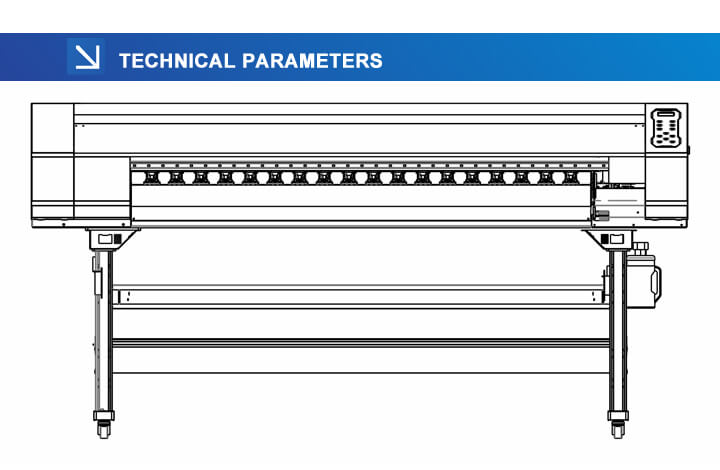

Model: Fedar FD70-2 DTF Printer

Printing Width: 600mm

Max Resolution: 3200DPI

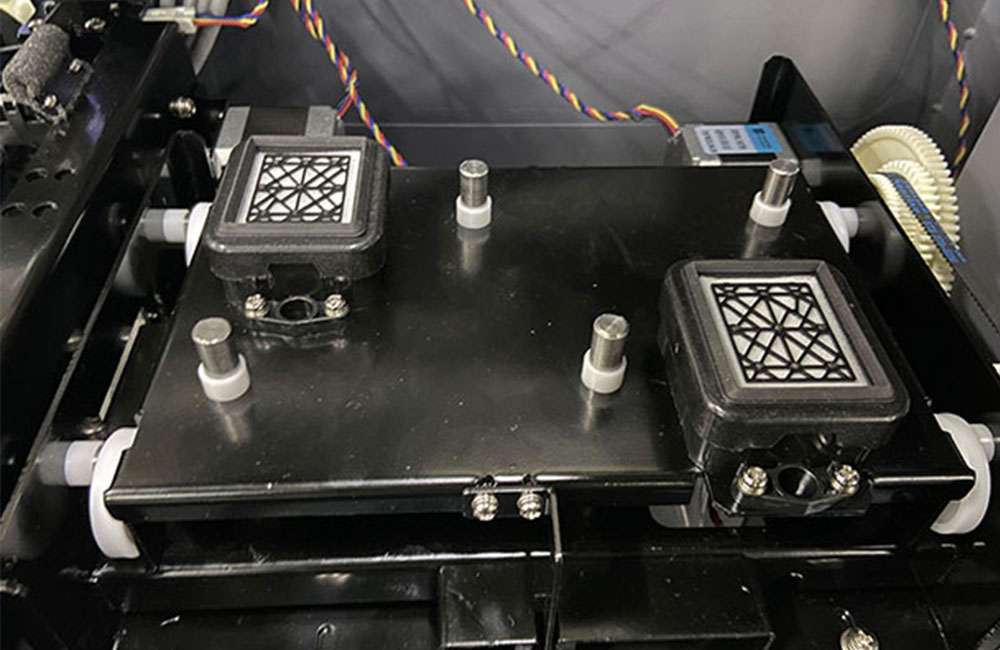

Print Head: 2 Epson I3200-A1

Max Speed: 8m²/h

TECHNICAL DATA:

| Medol | FD70-2(double-head) |

| Printhead | Type: EPSON I3200-A1 Quantity: 2 |

| Print Width | 600mm |

| Print Speed |

6 PASS:8m²/h 8 PASS:6m²/h |

| Ink Color | C M Y K + W |

| Ink Type | Pigment Ink |

| RIP Software | Maintop, FlexiPRINT |

| Transmit Port | Ethernet |

| Print Media | Pet Film |

| Print File Format | TIF, JPG, PDF Etc. |

| System Configuration | WIN7/WIN10, HARD DISK: 500G or more, GPU: ATI Discrete GPU Memory: 8G or more, CPU: Intel i5 Processor |

| Working Environment | Temp: 18C-30C Humidity: 35%-65% |

| Power | 50HZ/60HZ, 220V, 10A |

| Package Size | 1760*1000*750mm |

| Gross Weight | 210KG |

DETAILS:

Fedar FD70-2 60cm DTF Printer uses double Epson Original I3200-A1 Print Heads. Max Printing Width: 600mm. Max Resolution: 3200DPI. Max Production Capacity: 8 Sqm/Hr

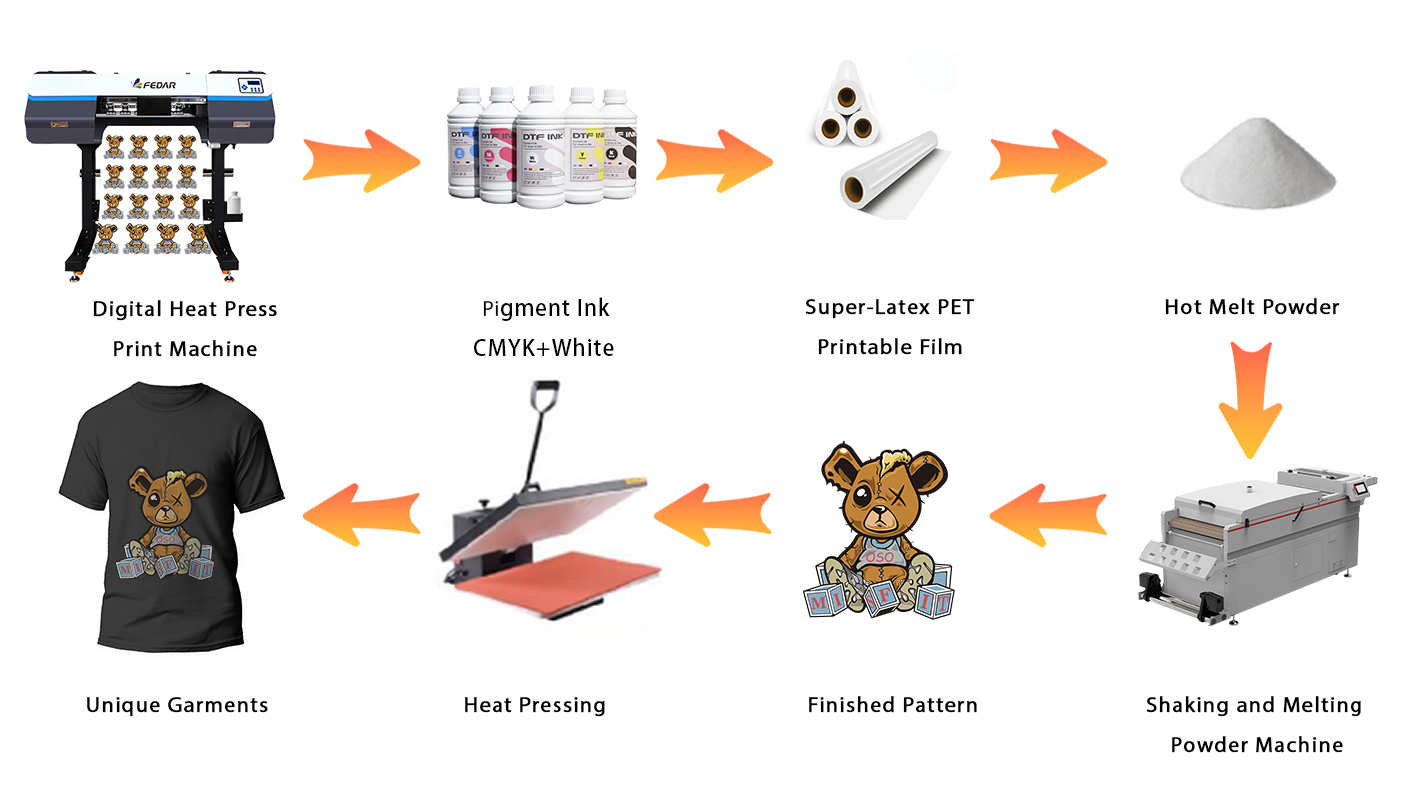

No need the plate making, easily to produce

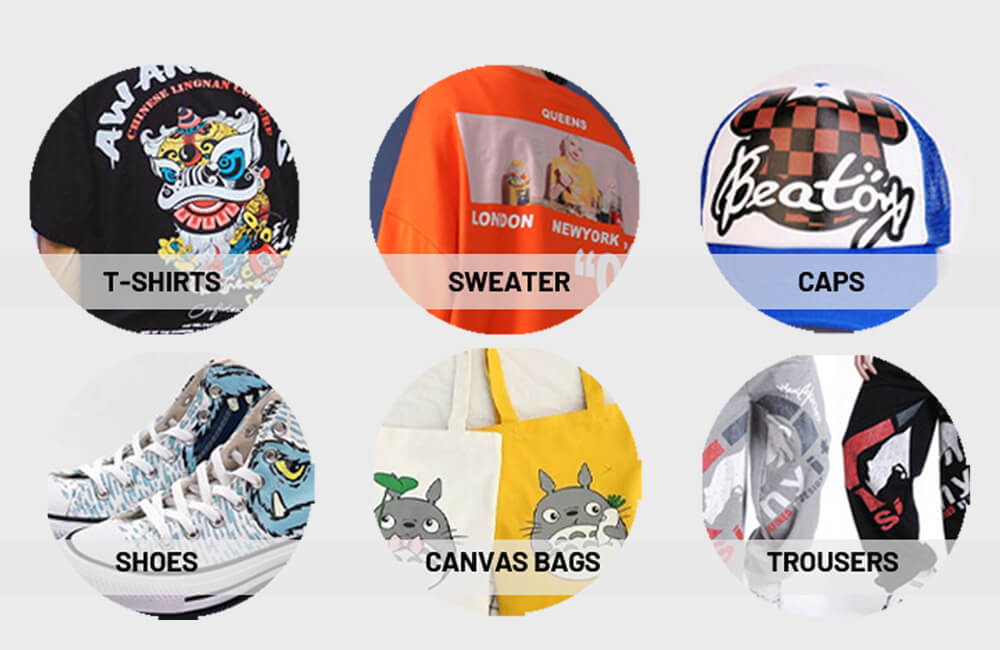

Fedar FD70-2 DTF PrintER can be widely used different kinds of fabrics, leather, bags, shoes and hats, clothing, socks, masks, gloves, umbrellas, plush toys, knitted underwear, swimwear, and other textile and fiber crafts, etc.

Fedar FD70-2 DTF Printer use Original Epson I3200-A1 Heads. Precision Core print head has proven high durability and extended service life. Precision made of Epson unique MEMS nozzles and an ink flow path ensure the perfectly round ink droplets are placed accurately and consistently.

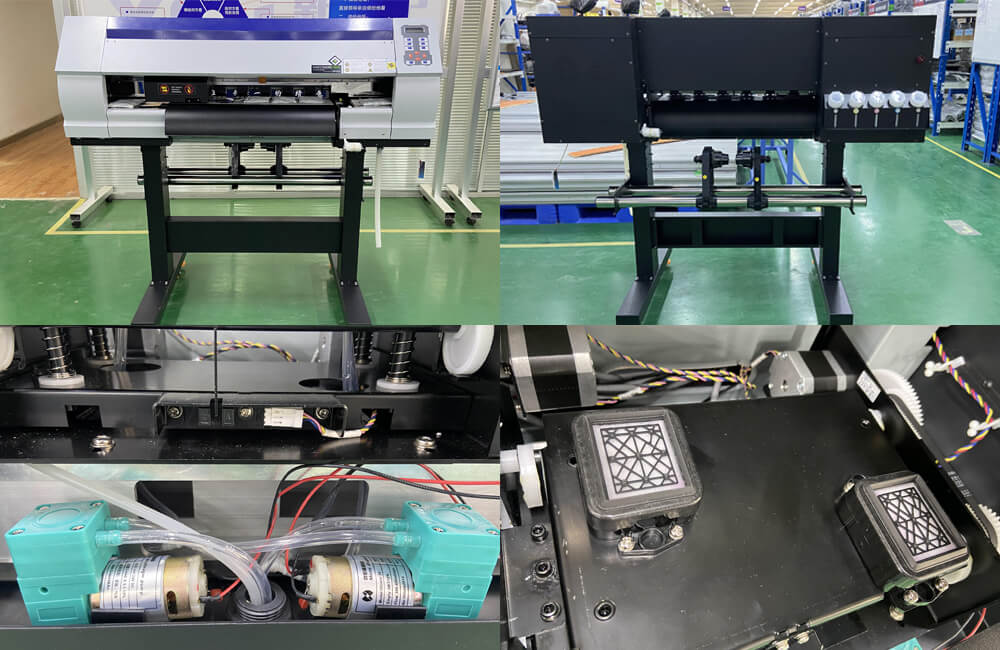

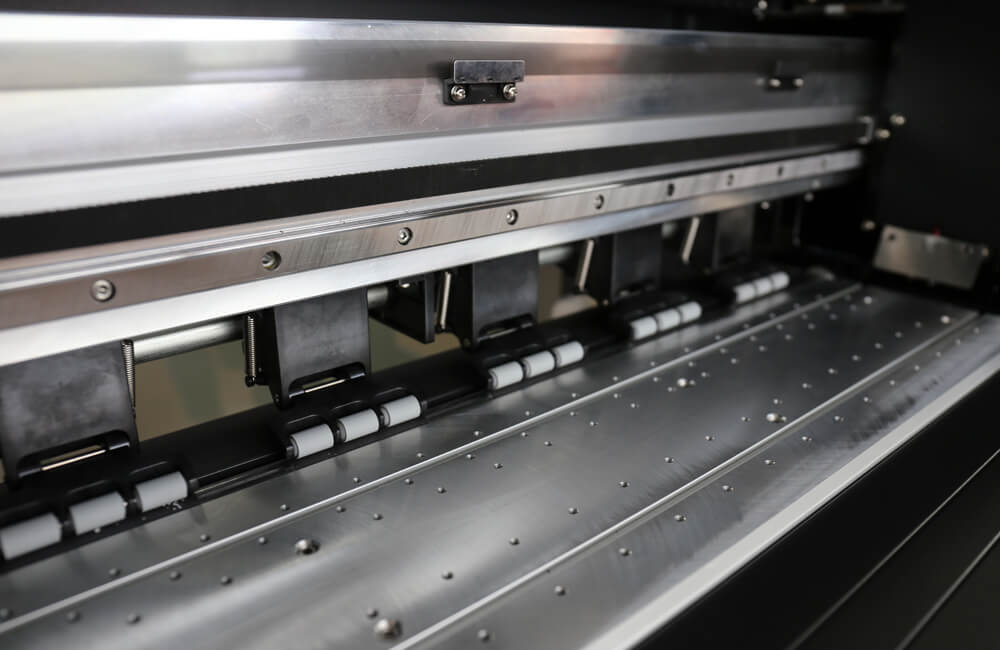

Capping Station of Fedar FD70-2 DTF Printer equipped with advanced intelligent nozzle cleaning and moisturizing device, providing safe and convenient nozzle cleaning and maintenance functions, making operation and maintenance more convenient.

Fedar FD70-2 60cm DTF Printer uses four 3L super-large-capacity ink tank with independent and continuous ink supply. The powerful continuous supply ink supply system provides support for the improvement of production efficiency, avoiding the frequent shortage of ink in production and the heavy work caused by back and forth inspection.

Fedar FD70-2 60cm DTF Printer core components are made of high-quality industry accessories such as Japanese THK ultra-quiet linear guide rails, Japanese NSK bearings, German IGUS INK chain, LEADSHINE servo motor, etc. All of these ensure the accuracy of the machine and the stability of long-term work.

Fedar FD70-2 DTF Printer uses assembly precision of the machine printing platform is controlled within plus or minus 7.5 wires, which lays the foundation for high-precision and high-quality production. The overall honeycomb aluminum alloy platform is hard-oxidized on the surface and will not deform for a long time.

Easy Use

Universal Matching

Suit for Digital PET Film Print

Offset Print Transfer, One-Time Forming

No Need Cut, No Need Tear, Less Manpower

Fedar FD70-2 DTF PrintER can be widely used different kinds of fabrics, leather, bags, shoes and hats, clothing, socks, masks, gloves, umbrellas, plush toys, knitted underwear, swimwear, and other textile and fiber crafts, etc.

Pigment Ink

DTF Hot Melt Film

TPU Hot Melt Shaking Powder

Model: Fedar FD70-2 DTF Printer

Printing Width: 600mm

Print Head: Two Epson I3200-A1 Heads

Printing Speed: 6pass: 8 Sqm/Hr 8pass: 6 Sqm/Hr

Interface: Gigabit LAN

Print Media: PET Film

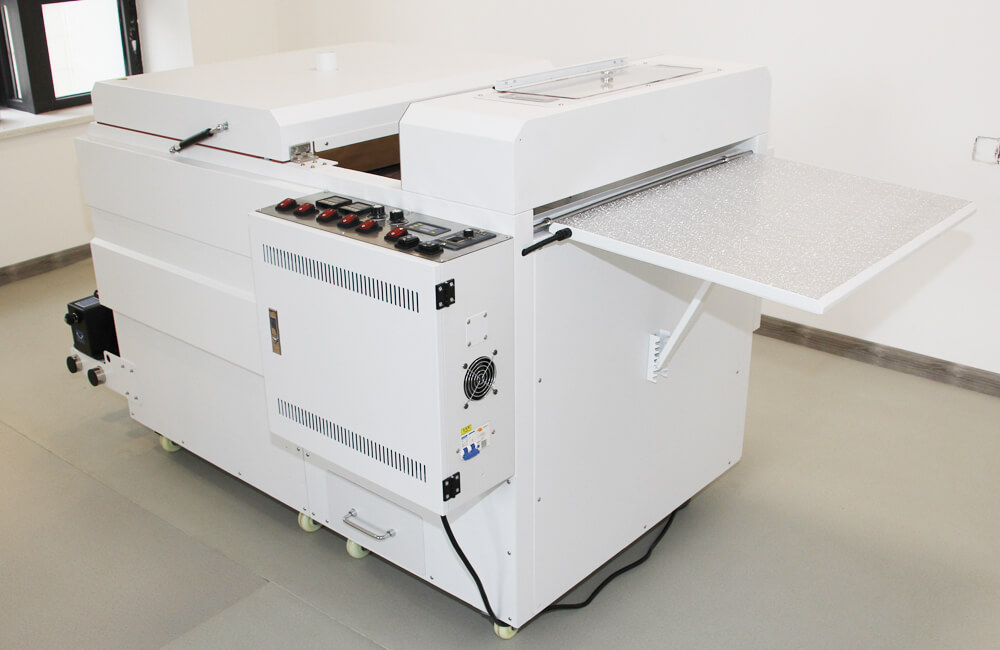

Drying Method: Extra Dryer Device

RIP Software: Maintop, Onyx, Photo Print

Ink Supply Method : Bulk Ink Supply System

Printing File Forms: TIFF, JPG, EPS, PDF, etc.

Media Transfer: Auto Taking-Up Media Device

Ink Type: Pigment Ink

If you need our products please write down any questions, we will reply as soon as possible.